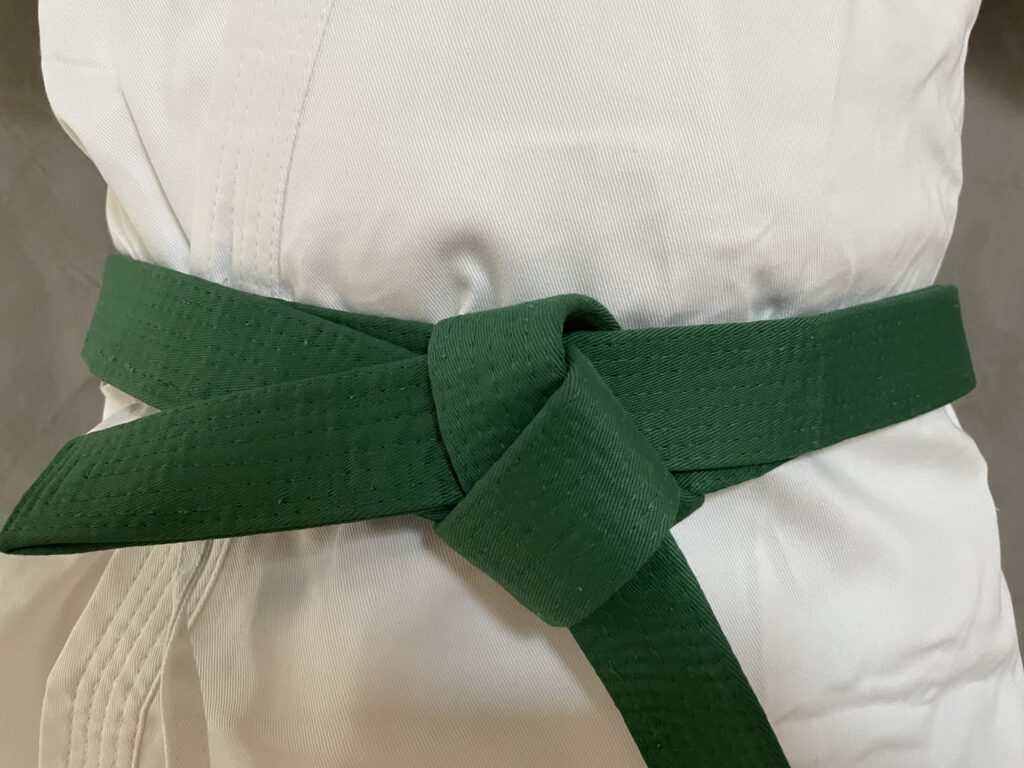

Kentucky Lean Six Sigma Green Belt Training and Certification

Contact Us

The use of Lean Six Sigma Green Belt methodologies in your professional life will have a huge impact on your career. Lean Six Sigma Certification on your resume reflects your commitment to bettering your technical awareness and analytical skills, as well as to the company you work at. The principles of Lean Six Sigma Experts of Kentucky Certification are found in many industries all around the world.

What Exactly Is Lean Six Sigma Experts of Kentucky Certification?

Lean Six Sigma is a series of approaches and techniques utilized by firms to improve production practices, minimize defects, and maximize productivity. The Lean Six Sigma credential validates professionals who can identify and eliminate risks, errors, or defects in a business operation.

Obtaining a Lean Six Sigma Certification usually necessitates a certain level of expertise and proficiency. The certification will improve your skills as a Process Management Professional, and also improve your credibility.

For example, individuals with a Lean Six Sigma Green Belt work on small-scale process growth programs. Typically, their job would require them to commit less than 50% of their time to Lean Six Sigma initiatives. However, the roles and job requirements for Lean Six Sigma Green Belts vary by organization.

Get Your Lean Six Sigma Certification Today

Green Belt certification is fitting for anyone responsible for enhancing existing systems and processes; these systems and processes may be non-standardized, with no specified measurements. Alternatively, the company might be seeking to reduce failures or production time in particular systems.

We offer nationally recognized Lean Six Sigma Green Belt training and certification. Our program, which is included in our four-week Black Belt option, may be taken individually or as the first step toward gaining your Black Belt. We became one of the first organizations to provide a curriculum that allowed students with no formal experience to pursue both the Green Belt and Black Belt programs simultaneously, to earn a nationally recognized Black Belt certification.

The ability for individuals from the same institute to finish the training together, even though they are advancing toward different Belt grades, is an added benefit of the Green and Black Belt certification options. This hybrid style encourages and helps groups to cooperate while still providing the opportunity to mix and match locations. We have common classroom projects as well as on-site solutions, such as Champion Services, which are built for executives who are only beginning Lean Six Sigma implementation.

Certified Lean Six Sigma Green Belt

These are consultants who are very experienced in the main and specialized aspects of the Lean Six Sigma methodology and can direct change within programs and/or serve as team members as part of more intricate improvement ventures, led by a Certified Black Belt, usually on a part-time basis. A Lean Six Sigma Green Belt understands all aspects of the Lean Six Sigma methodology, including subject matter experience in the Define, Measure, Analyze, Improve, Control (DMAIC) phases as described by the IASSC Lean Six Sigma Green Belt Body of Knowledge. A Lean Six Sigma Green Belt is well-versed in Lean Six Sigma implementation, performance, study, and application.

This is the credential for you if you want to be acknowledged for your experience in effectively applying for Lean Six Sigma technology and techniques in your enterprise. The certification has long been needed for Quality Specialists who choose to advance in their Quality Management careers. The certification process is comprehensive, with several levels of certification aimed at educating specialists in advanced skill sets. It is also a benefit that can provide you with pay raise opportunities. Obtaining a Lean Six Sigma Green Belt certification is a significant step towards being a Master of the Lean Six Sigma concepts and leading business development efforts. A Lean Six Sigma Yellow Belt identifies possible areas for development and plays an important part in implementing the necessary changes, drawing on the theories and skills gained through LSS Yellow Belt certification. As a Lean Six Sigma Green Belt you will be able to carry out small-scale growth projects that, if effective, will achieve a true sense of accomplishment. There are few things more motivating than knowing you've had a genuine impact on the company's competitiveness and financial performance. While LSS Yellow Belts aid in the start-up of an improvement project – generally by gathering data and designing method diagrams – Green Belts are actively engaged throughout the project. They are the ones that implement the modifications, with supervision and guidance from an LSS Black Belt or Master Black Belt. Professionals with LSS Green Belt credentials will typically devote between 25% and 50% of their working hours to Lean Six Sigma initiatives. They are well-known as Lean Six Sigma experts and as a motivating force for success in their organization. Green Belts are full-time workers in a corporation who have been trained in the Six Sigma enhancement methodology and would direct a Process Improvement Squad. Most of their time is spent during the Six Sigma project planning period on the decision-making and strategy-building elements of key products. They provide a greater understanding of the whole methodology and collaborate with cohesive Project Managers to provide feedback and drive performance goals. Why Choose Lean Six Sigma (LSS) Certification For Your Career In Quality Management?

Why Do I Need A Lean Six Sigma Green Belt?

What Are The Roles And Responsibilities Of The Green Belt?

What Jobs Require LSS Green Belt Certification?

Professionals with LSS Green Belt credentials may apply for a variety of occupations, including, though not limited to the following:

Quality Development Manager – Quality Development Managers are responsible for optimizing production efficiency through the assessment and testing of operational procedures, which is a standard activity in the manufacturing sector. They will be in charge of promoting continuous improvement of key processes and systems, defining innovative success benchmarks, and executing long-term business-beneficial programs.

Quality Engineer – Quality Engineers are responsible for ensuring that the company’s products and services fulfill customer needs. It will include working with a variety of stakeholders, including customers, design divisions, suppliers, and manufacturing staff, to identify any issues that may affect the overall output of the final product. Quality engineering is in control of creating all quality-related documents, as well as preparing and carrying out quality tests.

There are so many areas or regions where we offer these services with most of them being cities.

However, if you need any of these services, you need to contact us. The list below comprises the areas where we offer these services.